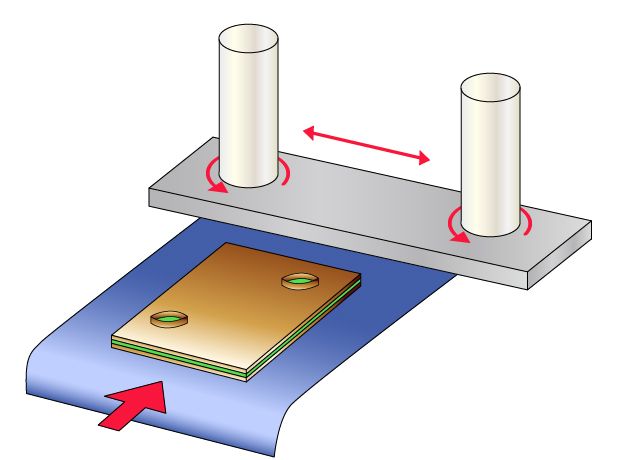

Vibration Sander machine

It is ideal for scrubbing to remove burrs deburring, pre-plating and polishing to remove protrusion after plating.

It reduces the defect rate of printed circuit board production.

MVS-602B3

- Uses a vibration type to achieve fuzzy, uniform polishing.

Features

- Polishes a wide range of surfaces.

- High cutting performance ability for protrusions that are difficult to remove even with buffing.

- Quick and Easy, one-touch installation of abrasive tools replacement.

- Orbital (Orbit = circular rotation), non-directional polishing be done.

Specification

| Abrasive material sheet | Maximum available width 650mm |

|---|---|

| Machine unit dimensions | 1540(W) × 1435(D) × 1450(H) mm |

| Machine Gross weight | 1,750kg |

| Electric power requirements | 3 phases 200V 3.5kw |

| Transport conveyer speed | 1.0 – 4.0m/min |

| Spindle revolution | Diameter 5mm 500 – 1800rpm |

| Oscillation cycles | Oscillation stroke 20mm 27cpm |

| Buff roll pressure control (Auto adjustment pressure control) |

Adjustment for load pressure by load cell electric cell. |

| Available work thickness | 0.06mm – 3.2mm |

| Scrubbing sheet exchange method | One-touch attachment on and removal of polishing tools as PAD by air cylinder lock system Fixing abrasives with Velcro tape |

*Specifications are subject to change without notice for improvement.